An Investigator extruder is one of the most important things on a 3D printer. When it comes to the functions of the extruder, it has vital functions on the printer. When the time comes to the movement of the filament, the extruder plays a very big role in ensuring that the filament moves to the hot area where it is melted down. When it comes to the extrusion of the filament, the melted filament is then extruded into very thin layers. The extruder is not as hot as the hot end.

The extrusion process I'd enhanced because the extruder is not as hot as the hot end. The extruder is also referred to as the cold end because when the filament passes through it , it becomes very cold. We have different types of extruders. The Bowden extruder is designed in a very special way that makes it function in its unique and special way. The functioning of the Bowden extruder system is different from the other types of extruders. To know more, check it out!

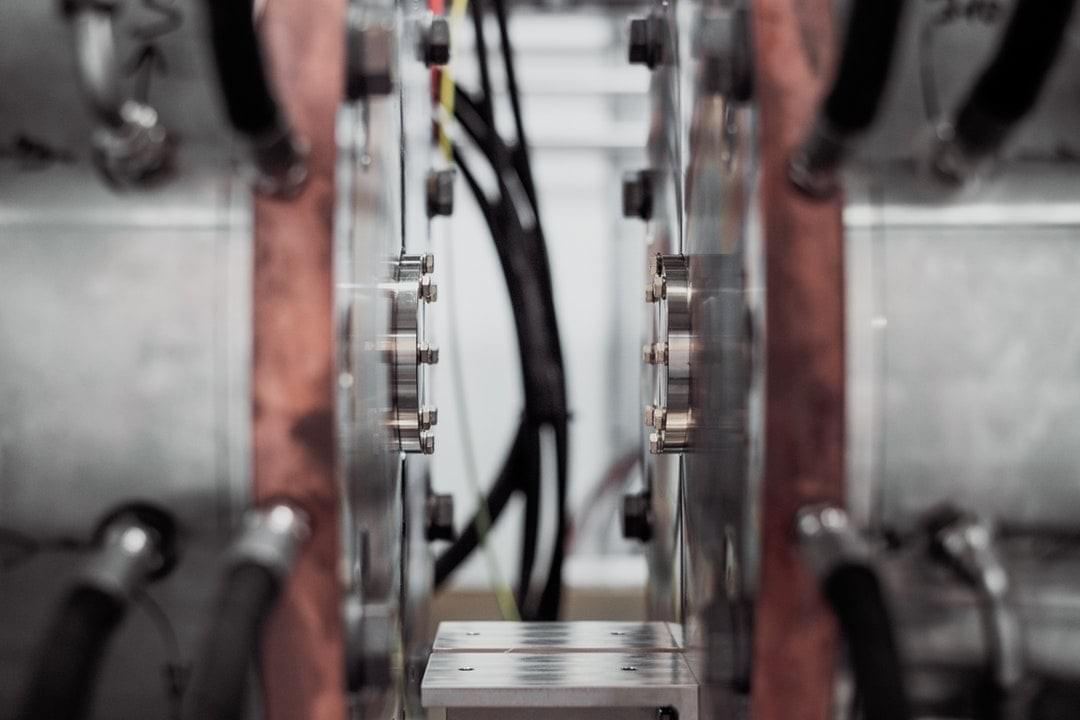

Another type of extruders is the direct extruders. They also work in their own unique way. When it comes to their components, they have different components that make them to work differently from each other. The different types of extruders also have some similarities. They both have motors. When it comes to the functions of the motors, it is evident that they perform a very big role in ensuring that the extruders run in a more efficient manner. The motors function depending on the arrangement of the extruder system. This means that the arrangement of the extruder system is the one that determines how the motor works.

Filaments are also available in both extruders. When it comes to the roles of the filaments on the extruder system, it is evident that they perform the same functions on all the different types of extruders. The idler is available in the extruders. When it comes to the functions, it also serves the same role in all the different types of extruders. When it comes to the functions of the idlers, the perform a very role of ensuring that the filaments are held properly so that they can undergo extrusion.

When it comes to the benefits of the different types of extruders, it is evident that each of the extruders has advantages. The direct extruder is of great advantage because it takes the filament a very short distance to arrive at the hot end for melting. The short distance the filament takes is very beneficial because it makes the printing process more flexible and fast. The direct extruders also have disadvantages. Mass is mandatory when it comes to reaching at the hot end. Learn more about extruder system.